drying bottles in tyvek after autoclaving|autoclaving at 121c : import Large heavy bottles, such as 20 L bottles, should also have a small amount of distilled water (WFI or purified) placed inside them to help generate steam when they are being sterilized dry . Autoclaves use water in mainly three processes: 1. Steam generation The design of the autoclave produces high-temperature, pressurized steam to kill viruses, bacteria, and . See more

{plog:ftitle_list}

Découvrez nos modèles d’autoclaves verticaux. Technologie avancée, qualité supérieure et performances exceptionnelles.

Large heavy bottles, such as 20 L bottles, should also have a small amount of distilled water (WFI or purified) placed inside them to help generate steam when they are being sterilized dry .To avoid recontamination after sterilization, packages must be dry after completion of the drying cycle when they leave the sterilizer. A ‘wet pack’ has moisture on or in the pack when removed from the autoclave. Moisture may be evident as visible dampness, droplets, or puddled water on or within a pack. Wet packs are subject to ‘wicking’ – they allow microorganisms to enter .Improve the microbial barrier and cleanliness of your sterilization wrap. Manufactured and packaged in a controlled cleanroom environment Autoclavable at 121 to 125 °C Tear and puncture resistant.

a)Autoclave: Loosen the cap on the agar bottle and autoclave the bottle at 15 psi for five minutes. While wearing heat-protective gloves, carefully remove the hot bottle and let it cool to between 75–55°C before pouring. This takes approximately 15 minutes. b)Water Bath: Loosen the cap on the agar bottle and place it into a water bath.After drying, the autoclave starts the cooling phase, reducing the temperature and pressure of the chamber to 80ºC. The accompanying image illustrates the operation of an AHS-DRY Series autoclave during the drying phase. These models are equipped with electric heating elements and an integrated water tank. During the cooling phase, the water . The temperature the user has entered exceeds the autoclave’s maximum temperature allowance. Meet the People Behind Our Autoclaves >>> 2. The load is damaged by the autoclave. There are a few ways that an autoclave can damage a load. The first is melting.%PDF-1.5 %µµµµ 1 0 obj >>> endobj 2 0 obj > endobj 3 0 obj >/Font >/ProcSet[/PDF/Text/ImageB/ImageC/ImageI] >>/MediaBox[ 0 0 595.32 842.04] /Contents 4 0 R/Group .

A concise reference chart providing general compatibility guidelines for polymers and polymer families with major sterilization technologies. The sterilization methods covered are autoclave, dry heat, ethylene oxide gas (EtO), gamma irradiation and elec tron beam (E-beam) radiation. Created Date: 1/23/2019 12:07:53 PM

dry cycle after autoclaving

The items in my autoclave are not drying and are coming out wet (i.e. wet packs) A wet pack can occur for any number of reasons. There is no single place to look first. There are, however, certain operator behaviors and processes as well as mechanical failures within an autoclave that could lead to the moisture being retained inside an .%PDF-1.7 %âãÏÓ 4276 0 obj > endobj 4288 0 obj >/Encrypt 4277 0 R/Filter/FlateDecode/ID[1564B57341670E45ABF57AA58477559A>]/Index[4276 29]/Info 4275 0 R/Length 79 .Drinking water is autoclaved by placing filled water bottles in wire baskets and covering the wire basket with a suitable cover (e.g., Tyvek, or similar material) prior to autoclaving. Autoclaved water bottles remain covered from time of autoclaving until time of use. The shelf life of sterilized drinking water is 1 month from the sterilization . Tyvek/plastic – These pouches are for use in Vaporized Hydrogen Peroxide (VHP) and EO sterilization. A sterilization pouch consists of two main parts: medical grade paper, or Tyvek ®, and a clear plastic film, held together by heat seal or with an adhesive. These materials are specifically designed to allow penetration of chemicals, heat .

autoclaving and maintains a microbial barrier post . sterilization. The wrapping allows for parts and equipment to be moved throughout the facility and within the clean rooms without compromising the critical product contacting surfaces. Double wrapping or using a wrapping material that is compatible with manual application of surface

autoclaving at 121c

Tyvek® 1422A autoclave bags can be used as either the inner, or outer bag for the steam sterilization of pharmaceutical change parts. Tear and puncture resistant Designd to be heat sealed closed. Shop Keystone Cleanroom Products 1422A Tyvek® Autoclave bag with Steam Indicator at Thomas Scientific. Cooling and Drying: After the sterilization cycle is complete, the chamber is slowly depressurized and the items inside need to be cooled and dried in order to avoid any remaining moisture. Unloading and Storage: Once the cycle is complete and the items have cooled, they are carefully removed from the autoclave.

Tyvek® 1422A autoclave bags with steam indicators can be used as either the inner, or outer bag for the steam sterilization of pharmaceutical change parts.The sterilization pouches are designed for quick, easy presentation of sterile items. Flat seals ensure seal integrity, and that the bags will not open up in steam autoclaves or be affected by gas. Sterilization pouches facilitate effective .

Discover the primary autoclave sterilization cycles and learn how to select the appropriate one based on the type of load to be treated. . It is the recommended cycle for sterilizing bottles with culture media or aqueous solutions. Learn more about the liquids cycle. 4. Cycle with drying.Tyvek® 1422A self-sealing autoclave bags can be used as either the inner, or outer bag for the steam sterilization of pharmaceutical change parts. Tear and puncture resistant; Convenient and reliable "dual seal"self-sealing closure; Eliminates need to cut material and the use of autoclave tape; Fast and consistent for equipment preparation area

Steam is effective at transferring thermal energy (compared to dry air) and can sterilise a load at 121°C in just 15 minutes. The majority of laboratory glass bottles are suitable for autoclaving. However, it is important to take note of some key differences between the types of glass products used in the lab as well as best practice methods . The strange scare, as reported in numerous media outlets, involved the staining of wrapping materials used to protect sterilized instrument trays during and after autoclaving. Because of the potential risk of contamination, the hospital was forced to suspend all of its surgeries — the impact of which meant the cancellation of 40-50 procedures .The terms Autoclave and Sterilizer are interchangeable and mean the same thing. ‘Autoclave’ is a term used mainly in laboratories whilst ‘Sterilizer’ is used more commonly for medical and pharmaceutical applications. An effective autoclave or sterilizer must .

dlc autoclave

Autoclaving for 60–90 min at 121 °C (15 psi), depending on the loading conditions, to achieve a waste temperature of at least 115 °C for 20 min is recommended. Effective autoclaving will depend on time, temperature, and steam penetration. Tubes, bottles, flasks, and bags should be loosely closed to allow steam penetration. Autoclave your medium for 25 minutes. After autoclaving, you can, of course, store the medium-agar mix in a toughened glass bottle then melt it in a microwave or water bath when needed. Make sure you use toughened glass bottles, or disaster can strike. Remember to use heat-resistant gloves when handling hot medium straight out of the autoclave. 3.

PureClean™ Autoclave bags are made from 1421B DuPont™ Tyvek®, which is a grade of uncoated, untreated, flexible Tyvek® material. It has been specifically designed for pharmaceutical use in steam sterilization applications. Keystone's PureClean™ Tyvek® material does not have a water soluble antistat agent applied to it during its manufacturing process. After cleaning, rinse the bottles with warm water to remove any soap residues. Inspecting: After cleaning, inspect the bottles for any signs of damage. Cracks or chips can not only weaken the bottle's structure but can also harbor microorganisms that may survive the sterilization process. Drying: Dry the bottles completely before sterilizing .For ® nearest 0.0001 g). Noveon polycarbophil, dry a weighing bottle and stopper at 45 ± 2°C in a vacuum Where B = Weight of sample, weighing bottle oven with a vacuum of 29 inches Hg for 30 and stopper after drying (to the minutes. nearest 0.0001 g). 2.

Borosilicate glass bottles are safe to autoclave as the material has a very good resistance to thermal shock. There is a much higher risk of breakage when autoclaving glass bottles made from soda lime or flint glass and while it remains possible to autoclave bottles of this type, the material doesn’t possess the same safety margin.Made from 100% Tyvek® and available in almost any size, these steam-sterilizable bags, tubing and wrappers are ideal for very large, heavy or irregularly shaped components such as carboys and stopper tracks or very small parts such as filling needles.

dlt autoclave

autoclave dry cycle

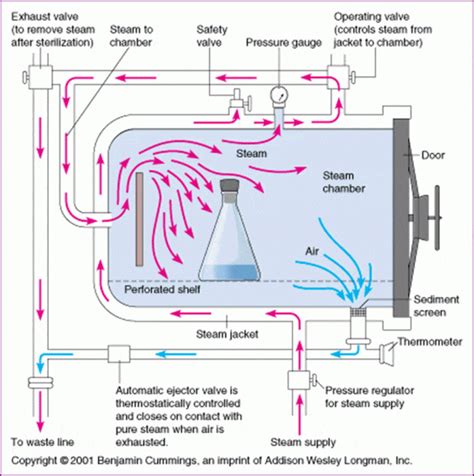

Autoclave kills microorganisms using saturated stem under pressure. Autoclave comprises of three parts: a pressure chamber, a lid and an electrical heater.

drying bottles in tyvek after autoclaving|autoclaving at 121c